During the world war II, in an effort to stem the rising tide of food shortages and provide work for millions of unemployed citizens, the Allied Nations ran a series of campaigns that encouraged people to grow their own vegetables and fruits called “Victory gardens”. Today another war called Coronavirus COVID-19 is creating various challenges for the people over the globe, we see countries implementing travel restrictions, social distancing measures, and work from home policies. Even the more developed countries are seeing their healthcare systems overloaded and fatigued by COVID-19. In this war instead of food shortages, we’re running out of personal protective equipment (PPE) for health care workers. Now it is the time for us to reboot our Victory gardens concept for 21st century using our technology which is available at our home.

The World Health Organization(WHO) has warned that severe and mounting disruption to the global supply of personal protective equipment (PPE) – caused by rising demand, panic buying, hoarding and misuse – is putting lives at risk from the new coronavirus and other infectious diseases. WHO estimated that 89 million medical masks are required for the COVID-19 response each month, along with 76 million examination gloves and 1.6 million medical goggles and facemasks.

What is a Face Shield and how does it help a Health worker?

Face shield will help health workers to cover their entire face when no mask is available. There are many types of face shields are available, but the type most medical workers are seeking is a piece of clear, curved plastic suspended in front of the wearer’s face by a headband. It helps stop bodily fluids and droplets, whether from a patient’s cough or a medical event such as a birth, from reaching the wearer’s eyes, nose, or mouth. A shield is usually meant to provide secondary protection when used with a primary piece of personal protective equipment (PPE) such as a face mask.

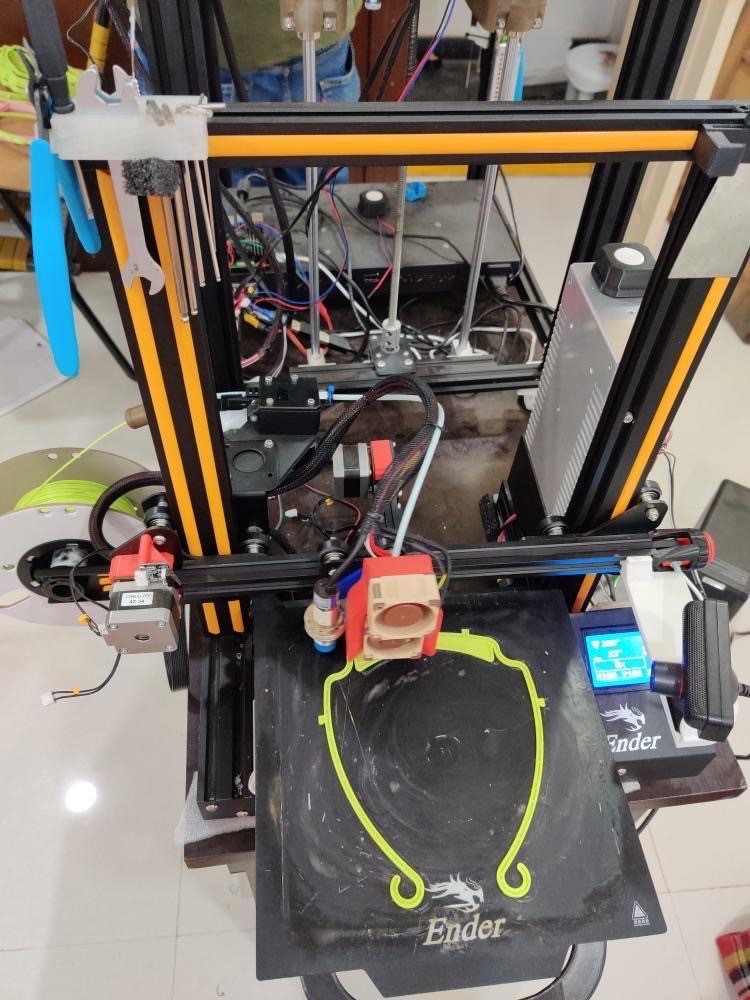

As there is a shortage of supply for PPE’s, many manufacturing units are looking into a way to produce face shields at a massive scale. Until these mass production operations ramp up, hospitals are still left with a shortage of PPEs. That’s where 3D printing comes in and you can design a prototype, print it and deliver the shield to a hospital in a day from your home. A single printer may be able to make 100’s of shields in a day.

A doctor couple(Chirag and Chetana) in Hyderabad, India who has 3D printers as a hobby printed more than 500 face shields and distributed in various Hospitals for their fellow doctors which they never thought that they could use them to make such a big impact during a crisis or that would be able to use it to give back to community. They have used the tools and skills to amplify a community of like-minded people and were able to help hundreds of front-line healthcare workers to protect themselves and others. In their words “we felt incredibly lucky for the opportunity to help”.

A Bengaluru-based factory is manufacturing face shields which will come in handy amid the shortage of masks as these allow an N95 mask to be utilised for a longer period of time.

Several 3D printing communities in Chennai are manufacturing face shields for medical professionals in the wake of the Covid-19 pandemic.

One Hyderabad-based startup has developed a sanitation tent that automatically sprays the disinfectant and it can be deployed in 10 minutes in any location. Another student innovator, a second-year Computer Science student, has developed web-based software to detect Covid-19 from chest X-Ray with about 90 per cent accuracy with the available datasets.

Technology can help us as a tool the curb the effects of COVID, even if marginally. What is needed, is a creative and socially responsible approach. Technology alone is not the solution, we all need to come forward in our individually capacity to do what best is possible to contribute towards the fight against COVID 19.

heads the Enterprise Process & Integration Practice at Happiest Minds and is responsible for driving strategy, execution, business, and technology across the desired market segments. He has a proven track record of delivering technical solutions and solution architecture in Integration technologies with over 11 years of experience, Santosh possesses a strong technical background in BPM & Integration technologies and also responsible for presales, Solutions, and implementation across various customers and projects. He is passionate about exploring various Integration, RPA, BPM & cloud-based technologies, and products.