Automation, driven by RPA, Artificial Intelligence (AI), Data Analytics, and Robotics, has begun changing the clockwork of almost all the industries from the essentials to a more advanced levels. AI and Automation are set to change the way we live and breathe in the coming years. Manufacturers require people, processes, and technology to integrate data across systems, orchestrate critical workflows, and deliver intuitive applications to employees in an increasingly competitive environment.

Breaking down these roadblocks requires:

Speed: To fast forward their time to market for a new product, drive organizational change and agile approaches that enable them to unite information across systems, orchestrate critical workflows, and deliver intuitive applications to employees.

Technology: Manufacturers need technology that leverages historical data and enables digital tracking for process improvement, performance monitoring, and risk mitigation for more vital decision-making and sharper insights. They can also utilize the power of AI, IoT, and Automation to overcome resource needs and operating costs.

Evolving business models: Manufacturers must improve how they collaborate with suppliers, design new products, go to market, and meet regulatory and compliance requirements. They can also generate new revenue streams through manufacturing as a service, remanufacturing, and build new partnerships. However, supply chain improvements and evolving business models must be supported by the right processes and technology.

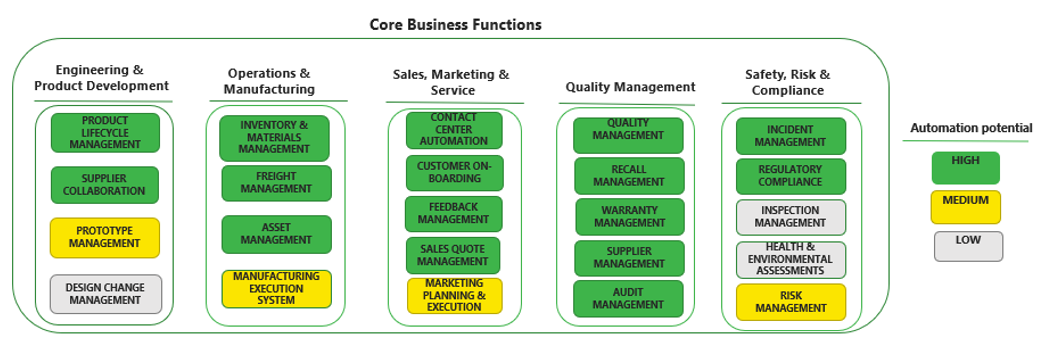

To overcome the above challenges, we have tried to identify potential areas across the manufacturing value chain and classified them into high, medium, and low potential areas for automation.

In this article, we will try to depict the manufacturers’ challenges in inventory management and how leveraging automation can enhance the overall inventory function.

Challenge faced by Manufacturers in Inventory Management:

- Dealing aptly with the dead stock

- Stock-outs

- Accelerated storage costs

- Disorganized order tracking

- Misplaced inventory stock

- Diminished customer loyalty

How automation can overcome these challenges:

- Supply & Demand Forecasting: Robotic Process Automation (RPA), with the aid of Machine Learning (ML) and Artificial Intelligence (AI), can help companies and business processes to determine the future demands and be ready to face the unexpected challenges in demand.

- Order Processing and Payments: Manual paperwork to process transactions can be entirely digitized, eliminates manual errors making it smarter and more self-driven.

- Monitoring stock level: It is essential to maintain accurate inventory levels, sending automatic notifications to managers when product stock levels are low, and auto-reordering products that go below a given level.

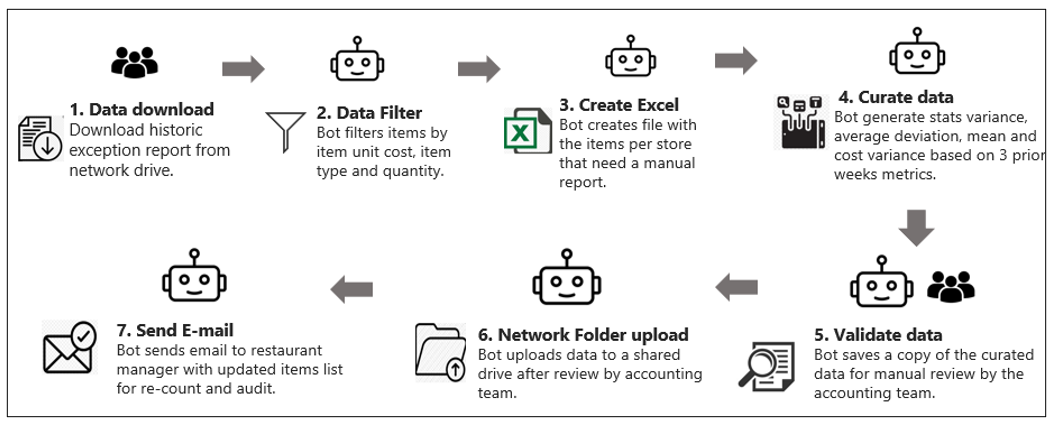

- Inventory auditing: Automatically read the input data from the inventory audit report and classify the records that needed validation and send individual emails to each store detailing items in need or recount.

- Customer quoting process: Automates labor-intensive data entry and activities in the quoting process, improved controls, and risk mitigation related to inaccurate vendor cost used to determine the customer price and margin.

Business Impact:

- Reduce costs

- Improve and optimize fulfillment

- Reduce turnaround time

- Nonstop performance

- Increase capacity without long buildup phase

- Boost employee engagement

- Increase quality by avoiding human error

- Improve executive decision making

In Inventory management, manufacturers can automate their inventory audit where organizations still rely on the physical inventory count method to manage a large amount of stock. Weekly reconciliation involves intensive manual labor dedicated resources per brand.

RPA can help in automating the solution in the below-mentioned way:

Maintaining accurate data on inventory levels sends an automatic notification to the managers when stock levels are low and reorder the products when they go below a given level.

Besides inventory management, as mentioned above, there is a lot of automation scope in various core business functions within the Manufacturing vertical. The first step for embarking on this journey is connecting your machines to collect the data, process the data, and take the right decisions. You can have better visibility into operational performance across your equipment and staff to automate processes and drive greater efficiency.

Senior Business Analyst, DPA COE, is a management professional with 6+ years of diversified experience across Corporate Strategy, Process & Automation Advisory, Process Consulting/Digital Transformation and BI/Analytics. He currently works with Happiest Minds in their Automation COE and is responsible for driving automation through advisory & implementation across new-age technologies – RPA & BPM with market-leading tools.